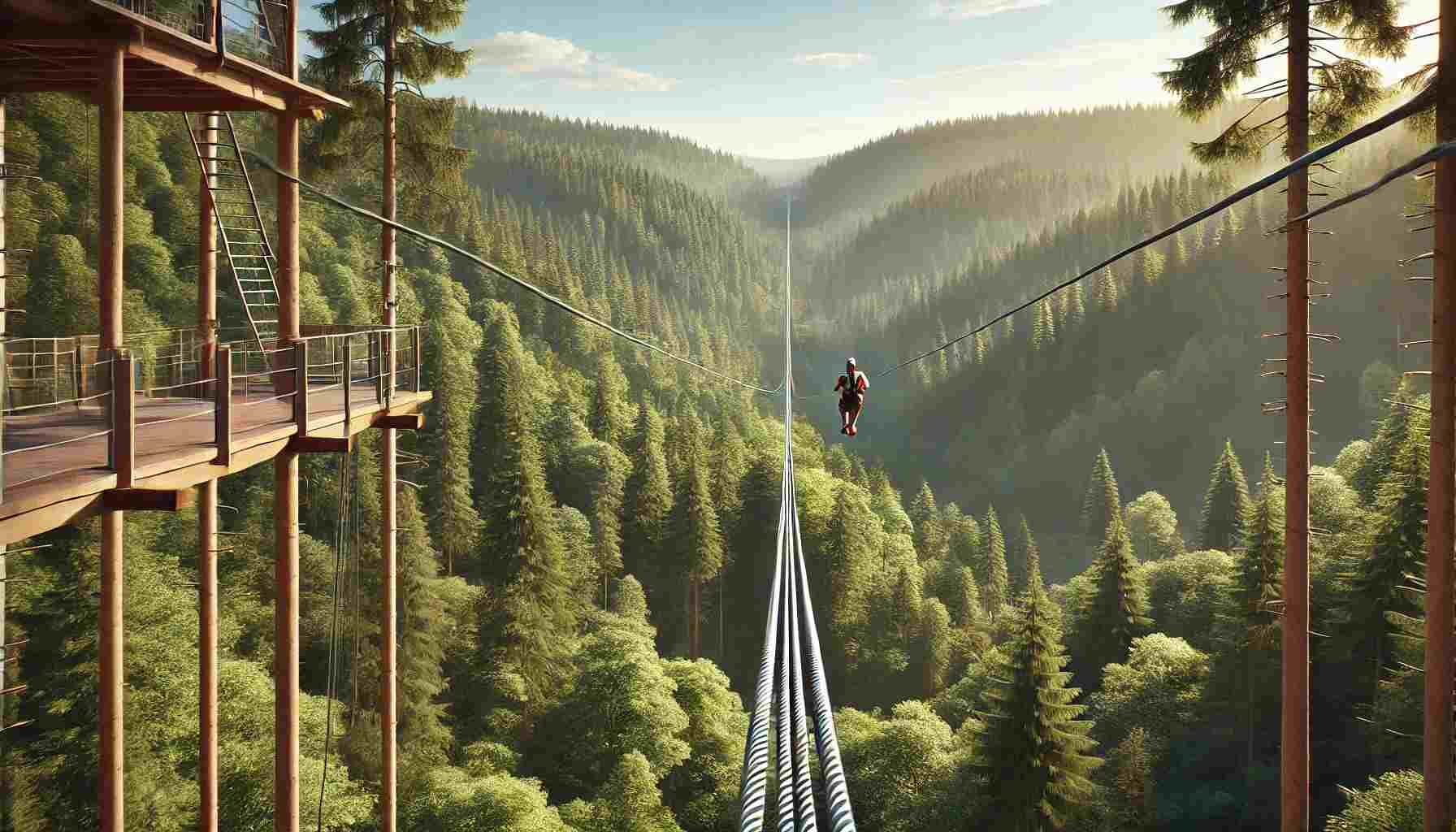

Designing a zip line requires precise calculations and considerations to ensure both safety and enjoyment. This comprehensive guide will walk you through the essential zip line design calculations, providing you with accurate, relevant information, and practical advice.

Introduction to Zip Line Design

Zip lines consist of a pulley suspended on a cable, usually made of stainless steel, mounted on an incline. They are designed to enable a person to travel from the top to the bottom of the inclined cable by holding on to or being attached to the freely moving pulley. The fundamental aspects of zip line design include:

- Cable Length and Slope

- Cable Tension

- Breaking Strength and Safety Factors

- Rider Weight and Speed

- Anchor Points and Foundations

Each of these elements requires careful calculation to ensure the zip line is safe, functional, and fun.

1. Cable Length and Slope

Calculating Cable Length

The length of the cable depends on the distance between the two anchor points. This is often measured in a straight line, but the actual cable length must account for sag. The formula to determine the cable length (L) when the distance between the two anchor points (D) and the sag (S) are known is:

L=D+2×(S×(2×H−S))L = D + 2 \times \sqrt{(S \times (2 \times H – S))}

Where:

- DD = Horizontal distance between anchor points

- HH = Vertical height difference between anchor points

- SS = Sag (usually between 2% and 7% of the cable length)

Determining the Slope

The slope is critical as it affects the speed of the rider. A typical zip line slope ranges from 3% to 12%. The slope can be calculated using the formula:

Slope(%)=(HD)×100\text{Slope} (\%) = \left( \frac{H}{D} \right) \times 100

Where:

- HH = Height difference

- DD = Horizontal distance

2. Cable Tension

Cable tension is a crucial aspect of zip line design as it impacts the sag and the rider’s speed. The tension must be sufficient to support the rider’s weight and the forces exerted by their movement. The tension (T) can be calculated using:

T=W×D2×ST = \frac{W \times D}{2 \times S}

Where:

- WW = Weight of the rider

- DD = Horizontal distance

- SS = Sag

Higher tension reduces sag but increases the forces on the anchor points.

3. Breaking Strength and Safety Factors

Breaking Strength

The cable’s breaking strength is the maximum force it can withstand before failing. This value is provided by the manufacturer. For safety, it is essential to use a cable with a breaking strength at least five times the maximum expected load.

Safety Factor

The safety factor is a multiplier applied to the expected maximum load to ensure safety. For zip lines, a common safety factor is 5. This means if the maximum load is 200 kg (including rider and equipment), the cable should have a breaking strength of at least 1,000 kg.

Safety Factor=Breaking StrengthMaximum Load\text{Safety Factor} = \frac{\text{Breaking Strength}}{\text{Maximum Load}}

4. Rider Weight and Speed

Rider Weight

The zip line must accommodate the heaviest expected rider. The total weight includes the rider, their equipment, and any additional forces exerted during the ride.

Calculating Speed

The speed of the rider depends on the slope and the distance. A steeper slope and longer distance increase the speed. The approximate maximum speed (V) can be calculated using:

V=2×g×HV = \sqrt{2 \times g \times H}

Where:

- gg = Acceleration due to gravity (9.81 m/s²)

- HH = Vertical height difference

5. Anchor Points and Foundations

Anchor Points

The anchor points must be strong enough to withstand the forces exerted by the tensioned cable and the moving rider. Trees, poles, or specially constructed towers can serve as anchor points. The strength of the anchor points should be calculated considering the maximum tension in the cable and a safety factor.

Foundations

If using poles or towers, the foundations must be stable and strong enough to hold the anchor points securely. The depth and construction of the foundations depend on the soil type, the height of the poles, and the forces exerted by the cable.

Practical Considerations and Best Practices

Selecting the Right Cable

Stainless steel cables are commonly used for zip lines due to their strength and durability. When choosing a cable, consider the diameter and construction. A 7×19 construction (seven strands of 19 wires) provides flexibility and strength.

Inspection and Maintenance

Regular inspection and maintenance of the zip line are critical for safety. Inspect the cable, anchor points, and equipment for wear and damage. Replace any worn or damaged components immediately.

Legal and Safety Standards

Adhere to local regulations and safety standards when designing and installing a zip line. This may include obtaining permits, conducting safety assessments, and following specific design guidelines.

Tools and Resources

Calculators and Software

Several online calculators and software tools can assist with zip line design calculations. These tools can provide precise measurements and help visualize the design.

Professional Assistance

Consulting with a professional engineer or a zip line design company can ensure your design meets all safety standards and regulations.

Conclusion

Designing a zip line involves a series of precise calculations and considerations to ensure safety and functionality. By understanding and applying the principles of cable length and slope, cable tension, breaking strength, rider weight and speed, and anchor points, you can design a zip line that is both thrilling and safe. Regular maintenance, adherence to safety standards, and professional consultation are essential to the success of your zip line project.

By following this comprehensive guide, you’ll be well-equipped to create a zip line that offers an unforgettable experience for all who ride it. Remember, safety is paramount, so take the time to plan, calculate, and construct your zip line with care.

For purchasing zip line kits and equipment, check out Amazon’s selection of zip line kits. These kits include everything you need to set up a safe and exciting zip line in your backyard or adventure park.

Here’s Everything You Need to Know About Commercial Zip Line Trolleys

Additional Resources

- American National Standards Institute (ANSI) – Z359 Fall Protection Code

- Association for Challenge Course Technology (ACCT) – Zip Line Standards

- International Association of Amusement Parks and Attractions (IAAPA) – Zip Line Safety Guidelines