If you’ve ever dreamed of soaring through the treetops, feeling the wind rush past you as you zip along a cable, then you’re not alone. Ziplining has become an increasingly popular adventure activity, attracting thrill-seekers and nature enthusiasts alike. But have you ever wondered how these exhilarating ziplines are made?

Ziplines are made by installing a sturdy cable between two points, such as trees or towers. Professional ziplines require careful planning, including choosing the right location, engineering the cables, platforms, and trolleys, and implementing advanced braking systems for rider safety.

In this comprehensive guide, we’ll delve into the intricate process of designing, constructing, and ensuring the safety of ziplines, covering everything you need to know about the creation of this adrenaline-pumping attraction.

The Evolution of Ziplines

Before we dive into the nuts and bolts of zipline construction, let’s take a moment to appreciate how far ziplines have come from their humble beginnings. In their simplest form, ziplines are nothing more than cables stretched between two points, often with a pulley system for riders. These homemade ziplines can be found in backyards, providing short and often unsafe thrills.

However, in the realm of professional ziplines, there’s a world of difference. These ziplines are carefully designed and constructed with safety as a top priority. As the demand for more thrilling and sophisticated zipline experiences has grown, ziplines have evolved to meet these expectations. Today, ziplines offer longer rides, higher throughput, and landing areas with convenient unhooking options, creating a safer and more enjoyable experience for riders.

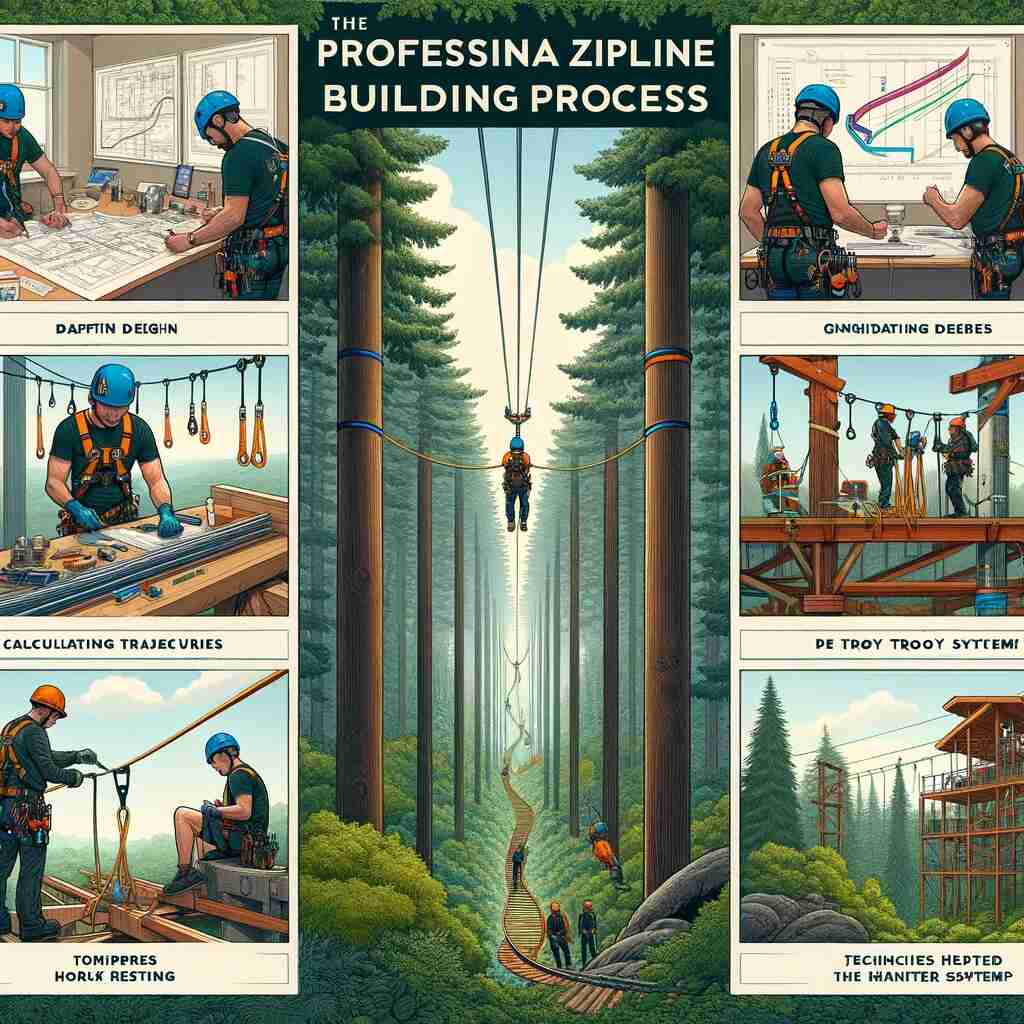

The Professional Zipline Building Process

Building a professional zipline is a complex undertaking that requires meticulous planning, engineering expertise, and a commitment to safety. Here are the key steps involved in constructing a top-notch zipline:

1. Identifying Departure and Arrival Locations

The first step in building a zipline is identifying suitable departure and arrival locations for the course. It’s crucial to ensure that the slope angle is manageable, taking into account the braking systems to be incorporated. Professional surveying of the land and a cable sag analysis are essential. The sag analysis considers factors such as ground line contour, tower requirements, and cable sag for optimal slope and rider safety. It also takes into account different conditions, including ice. This rigorous approach ensures that the zipline is hung accurately for maximum safety.

2. Tower Height Requirements

Once the departure and arrival locations are determined, the next step is to calculate the tower height requirements. This involves engineering the towers and specifying the cable dimensions to ensure stability and rider safety. The tower design is a critical aspect of zipline construction.

3. Cable Specifications

Selecting the appropriate cable is crucial to the zipline’s safety and performance. Ziplines often use stainless steel or galvanized aircraft cables, known for their strength and durability. The cable specifications must align with the engineering requirements to ensure rider safety.

4. Construction Begins

With all the planning and design work completed, construction can begin. During this phase, towers are erected, cables are strung, and all components are assembled to create the zipline course. Safety protocols must be followed at every step to prevent accidents during construction.

5. Ensuring Safe Landings

One of the most critical aspects of zipline construction is ensuring a safe and controlled landing for riders. Traditional methods, such as relying on participants to brake with a glove or using bungee cords, are now outdated. Modern ziplines utilize advanced braking technology like the ZipStop, which employs opposing magnetic forces to slow down riders as they approach the landing platform. This technology enhances safety and provides a smoother experience for participants.

6. Staff Training and Ongoing Inspections

Even after construction is complete, the commitment to safety continues. Proper staff training is essential to ensure that operators can effectively manage the zipline and respond to emergencies. Ongoing inspections and maintenance are also critical to identify and address any issues that may arise over time. Safety should always be a top priority in zipline operations.

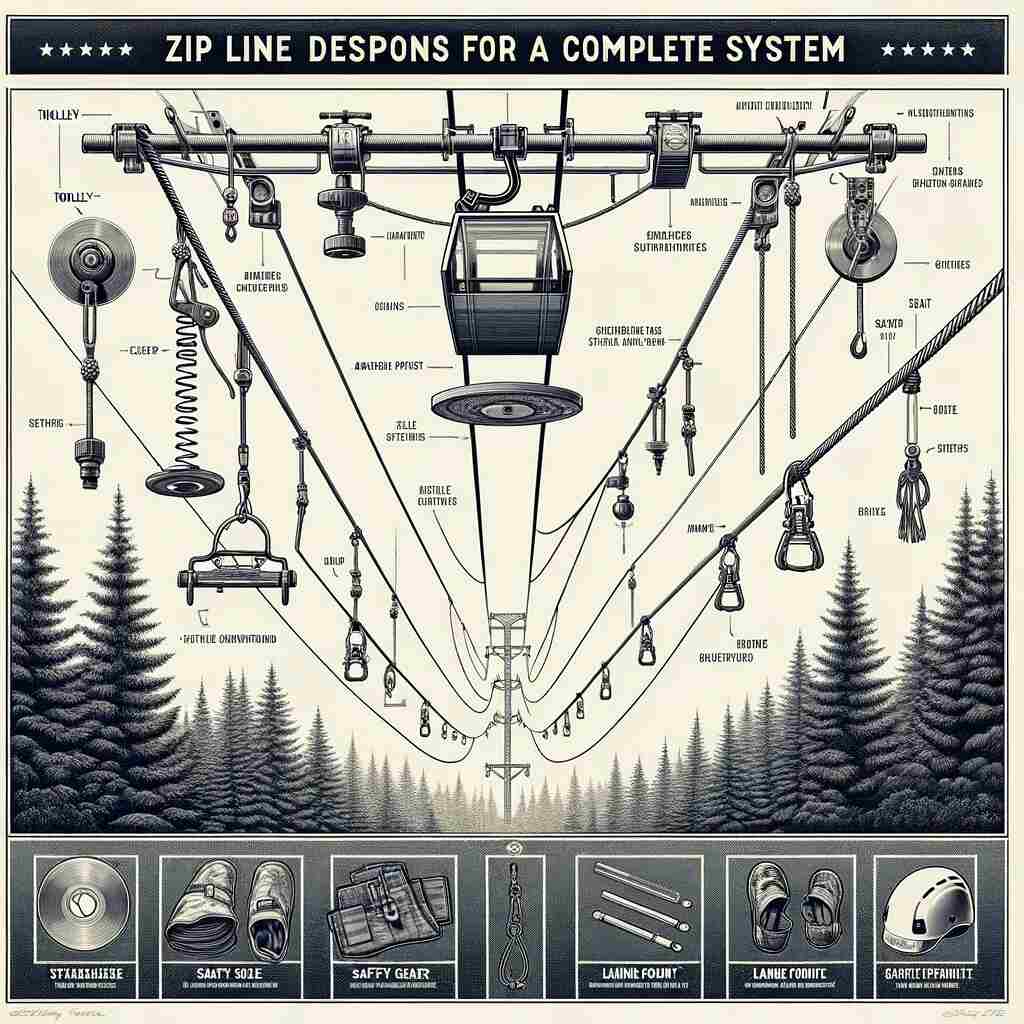

Zip Line Design: Components for a Complete System

To better understand the intricacies of zipline construction, it’s essential to examine the key components of a complete zipline system:

1. The Zip Line Cable

The cable is the defining element of a zipline, determining the length of the ride, the speed of the riders, and the overall experience. Materials such as stainless steel or galvanized aircraft cables are commonly used for their strength and durability.

2. The Zip Line Platform

Platforms serve as the starting and ending points for riders. Platform design depends on factors like topography, brake requirements, and space for guides and riders. Safety and comfort are paramount in platform design.

3. The Zip Line Trolley

The trolley is the rider’s vehicle along the zipline. It should be selected to match the speed of the zipline and the braking system at the end. Durability and reducing wear on equipment are key considerations in trolley design.

4. The Zip Line Brake

The brake is a crucial component of the ziplining experience. Passive braking, where riders don’t have to participate in braking, is preferred. Innovative braking technologies like the zipSTOP Zip Line Brake offer a safer and smoother way to stop riders at the end of the line.

5. The Emergency Backup Brake

An emergency arrest device (EAD) serves as a secondary brake in case the primary brake fails. Safety is paramount, and EADs ensure rider safety in the event of an emergency.

6. The Guides

Well-trained guides enhance the zipline experience by providing riders with information about the area, scenery, and safety procedures. Engaging guides contribute to a memorable and safe ride.

7. The Riders

The success of a zipline operation depends on attracting the right audience. Understanding your target audience and tailoring the experience to their preferences is essential for marketing and building a successful zipline.

8. The Zip Line Inspection

Regular inspections and maintenance are vital to ensure the ongoing safety and functionality of the zipline. Each component must be inspected, and routine maintenance performed to keep the operation running smoothly.

Zip Line Building: 7 Phases To Building A Zip Line

For those interested in a more in-depth look at the zipline construction process, here are the seven phases followed by professional zipline builders:

1. Site Discovery

The site discovery phase involves assessing the proposed location for the zipline. Trained professionals conduct a thorough walkthrough to plan take-off zones, landing zones, and anchor points. They also analyze visitor demographics and market potential to determine the site’s profitability.

2. Site Design

Site design is the beginning of zipline development, involving schematic drawings to identify and finalize the zip line corridors, potential obstacles, and topographical factors. It also includes finalizing the business plan, budget, and equipment selection.

3. Zip Line Engineering

Engineering is crucial to ensuring safety and compliance with industry standards. Technical feasibility studies are conducted to assess structural force, rider velocities, cable specifications, braking systems, and more. Safety and reliability are top priorities during this phase.

4. Fabrication of Parts

All zipline equipment and structures are designed and engineered, with an emphasis on quality and safety. Parts are fabricated in-house to ensure the highest standards are met.

5. Construction and Installation

The construction phase involves building the zipline course while adhering to safety protocols and project management timelines. Preserving the natural landscape is also a priority to integrate the attraction seamlessly with the environment.

6. Training Support and Operations

Once the zipline is ready, staff training and operations commence. Operators ensure that the zipline operates smoothly, with a focus on safety and providing riders with an unforgettable experience.

7. Safety Inspections

Regular safety inspections are mandatory to maintain the highest standards and prevent accidents. These inspections ensure that every aspect of the zipline is in working order and compliant with safety protocols.

Conclusion

In conclusion, the process of creating a zipline is a complex and meticulously planned endeavor. From selecting suitable locations and designing the course to engineering the components and ensuring safety, every step is essential to delivering a thrilling yet secure ziplining experience.

However, at its most basic, a zipline consists of a cable extended between two distinct points. In some instances, homeowners might rig up two cables between trees and utilize a pulley system for ziplining. These improvised ziplines are typically characterized by their shorter length, proximity to the ground, and varying degrees of safety measures.

Whether you’re an adventurer seeking the thrill of the ride or someone interested in the mechanics behind ziplines, understanding the intricacies of zipline construction adds depth to this exhilarating outdoor activity.