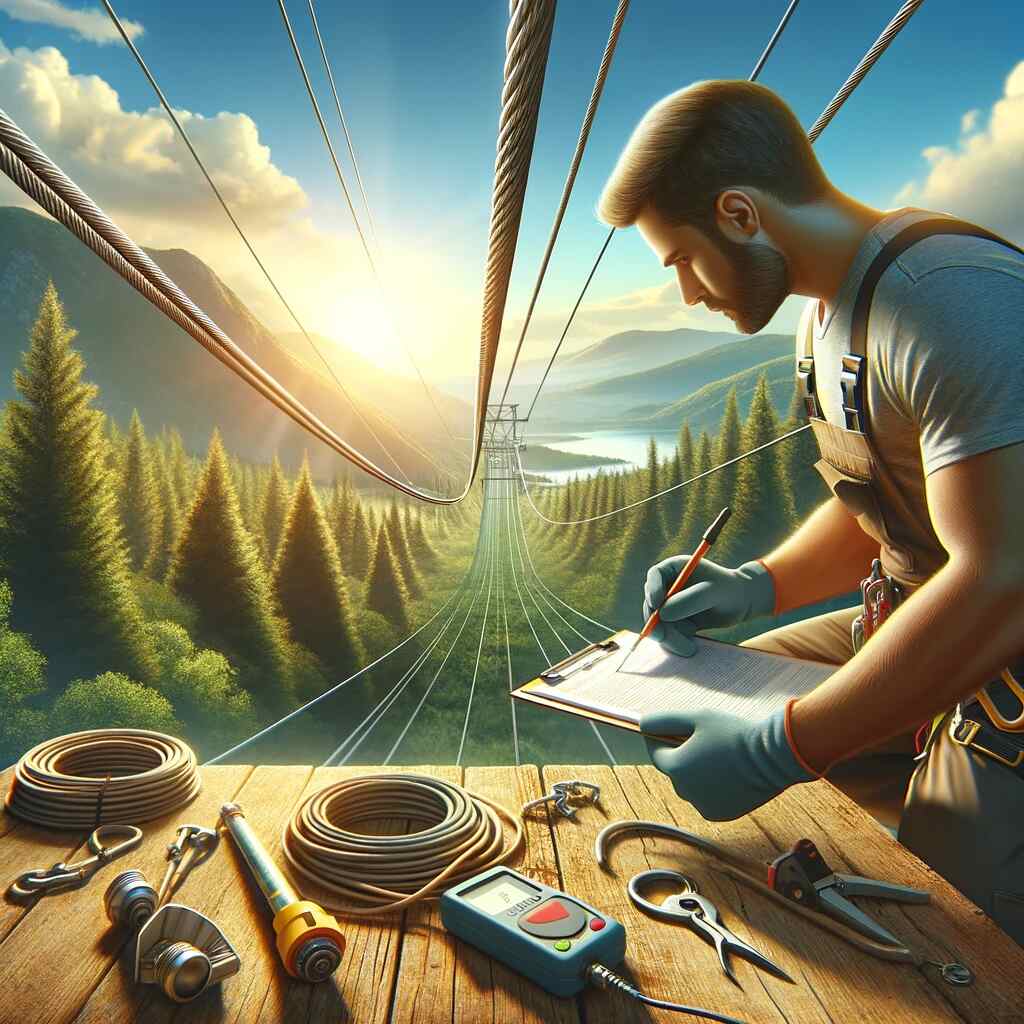

Ziplining is a thrilling adventure activity that has gained popularity around the world. Whether you’re zipping through dense forests or across breathtaking canyons, the safety of this experience heavily depends on the integrity of the zipline cable. Ensuring that the zipline cable is in good health and properly tensioned is crucial for the safety of riders.

In this article, we will delve into the techniques and methods used to measure the tension and health of a zipline cable, providing zipline operators and enthusiasts with valuable insights to ensure a safe and exhilarating experience.

The Importance of Zipline Cable Inspection

Before we dive into the methods of measuring the tension and health of a zipline cable, it’s crucial to understand why this inspection is so essential. The zipline cable is the lifeline for riders, and any compromise in its structural integrity can lead to catastrophic accidents. Here are some reasons why zipline cable inspection is critical:

Safety First

Safety is paramount when it comes to ziplining. Ziplining involves high speeds, significant heights, and inherent risks. Ensuring that the zipline cable is in optimal condition helps minimize the chances of accidents and injuries.

Preventing Catastrophic Failures

A damaged or improperly tensioned cable can lead to catastrophic failures, such as cable breaks or rider collisions. These incidents not only pose a severe risk to riders but can also have legal and financial consequences for zipline operators.

Extending Cable Lifespan

Regular inspection and maintenance can help extend the lifespan of a zipline cable. A well-maintained cable is less likely to develop serious issues, ensuring the long-term viability of the zipline.

Compliance with Regulations

Many countries and regions have regulations and standards governing the construction and operation of ziplines. Regular cable inspections are often a legal requirement to comply with these regulations and maintain operating licenses.

Measuring Zipline Cable Tension

Proper cable tension is crucial for the safe operation of a zipline. Tension that is too high or too low can lead to various problems, including excessive stress on the cable, premature wear and tear, and rider discomfort. Here are some methods for measuring zipline cable tension:

Tension Meter

A tension meter is a specialized tool designed to measure the tension in a cable accurately. It typically consists of a clamp that attaches to the cable and a gauge that displays the tension in pounds or Newtons. To use a tension meter, follow these steps:

a. Attach the clamp to the zipline cable at the desired measurement point. b. Apply tension to the cable until it reaches the desired level. c. Read the tension value on the gauge.

It’s essential to refer to the manufacturer’s guidelines for your specific tension meter, as different models may have slight variations in operation. Regular calibration of the tension meter is also crucial to ensure accurate measurements.

Sag Measurement

Another indirect method for measuring cable tension is by calculating the sag in the cable. Sag is the vertical distance between the lowest point of the cable and a hypothetical straight line connecting the two endpoints of the zipline. While this method is less precise than using a tension meter, it can provide a rough estimate of cable tension.

To measure sag:

a. Select a reference point on the cable, typically at the midpoint between the two endpoints. b. Measure the vertical distance from this reference point to the lowest point of the cable. c. Compare the measured sag to the recommended sag for your specific zipline system.

Keep in mind that sag measurement is affected by factors such as temperature, cable material, and load. Therefore, it should be used in conjunction with other tension measurement methods for a more accurate assessment.

Acoustic Tension Measurement

Advanced zipline systems may employ acoustic technology to measure cable tension. This method involves sending a sound wave through the cable and analyzing the time it takes for the wave to travel from one end to the other. By knowing the speed of sound in the cable material, the tension can be calculated.

Acoustic tension measurement is a non-invasive and relatively accurate method but may require specialized equipment. It’s suitable for larger zipline systems and those with complex cable routing.

Evaluating the Health of a Zipline Cable

Inspecting the health of a zipline cable involves assessing its physical condition, identifying potential weaknesses, and ensuring that it can withstand the forces and stresses it experiences during operation. Here are the key aspects to consider:

Visual Inspection

A visual inspection is the first and most fundamental step in evaluating the health of a zipline cable. Operators should regularly examine the entire length of the cable, looking for signs of wear, corrosion, or damage. Common visual cues indicating cable health include:

a. Surface rust or corrosion: Check for rust spots or corrosion on the cable’s surface, especially in areas exposed to the elements. b. Frayed or damaged strands: Inspect the individual strands of the cable for fraying, kinks, or breaks. c. Deformed or misshapen cable: Look for any bends, kinks, or deformities in the cable that could compromise its structural integrity. d. Loose or damaged attachments: Examine the connections between the cable and anchor points, ensuring they are secure and undamaged.

Regular visual inspections should be performed by trained personnel and documented to track any changes in the cable’s condition over time.

Magnetic Particle Inspection

Magnetic particle inspection (MPI) is a non-destructive testing method used to detect surface and near-surface flaws in ferromagnetic materials like steel cables. This technique can identify cracks, defects, and other discontinuities that may not be visible to the naked eye.

The MPI process involves:

a. Applying a magnetic field to the cable. b. Sprinkling iron particles (usually suspended in a liquid or powder) onto the cable’s surface. c. Observing the alignment of the iron particles, which will indicate the presence of any surface cracks or defects.

MPI is a highly effective method for identifying hidden flaws and is commonly used in industries where the structural integrity of materials is critical.

Ultrasonic Testing

Ultrasonic testing (UT) is another non-destructive testing method that can be used to assess the health of zipline cables. UT relies on high-frequency sound waves that are transmitted through the material. When these sound waves encounter a defect or irregularity, they are reflected back and detected by a receiver, allowing the operator to locate and assess the issue.

UT is particularly useful for detecting internal defects in the cable, such as voids, cracks, or delaminations. It is a precise method that provides valuable insights into the cable’s condition without damaging it.

Load Testing

Load testing involves applying a controlled load or force to the zipline cable to assess its performance under stress. While this method does not directly measure cable health, it helps determine whether the cable can safely support the intended load and is free from immediate structural issues.

Load testing typically follows these steps:

a. Attach a known weight or force to the zipline cable. b. Monitor the cable’s response to the applied load, including any deformation or elongation. c. Compare the observed behavior to established safety criteria and specifications.

Load testing should be conducted periodically and in accordance with industry standards to ensure the cable’s continued reliability.

Zipline Cable Maintenance and Best Practices

To maintain the tension and health of a zipline cable, regular maintenance and adherence to best practices are essential. Here are some recommendations for zipline cable maintenance:

Routine Inspections

Perform routine visual inspections of the entire zipline cable and associated components. Schedule these inspections at regular intervals based on usage and environmental conditions, and document the findings. Promptly address any issues identified during inspections.

Lubrication

Lubricate the cable periodically to reduce friction and wear. The type of lubricant and frequency of application will depend on the cable material and environmental factors. Consult the cable manufacturer’s recommendations for guidance.

Environmental Considerations

Consider the environmental conditions that the zipline cable is exposed to. Harsh weather, temperature fluctuations, and exposure to saltwater or chemicals can accelerate cable deterioration. Implement protective measures as needed, such as coatings or coverings, to mitigate these effects.

Training and Certification

Ensure that personnel responsible for zipline cable maintenance and inspection are properly trained and certified. This includes training on the use of specialized equipment and adherence to safety protocols.

Record-Keeping

Maintain detailed records of all cable inspections, maintenance activities, and load tests. These records are essential for tracking the cable’s history and compliance with safety regulations.

Periodic Load Testing

As mentioned earlier, conduct periodic load testing to assess the cable’s performance under stress. Follow industry standards and guidelines for load testing procedures and frequencies.

Replacement and Retirement

Zipline cables have a finite lifespan and will eventually need to be replaced. Establish a proactive plan for cable replacement based on usage, inspection findings, and environmental factors. Retirement criteria should be defined to determine when a cable is no longer safe for use.

Conclusion

Ensuring the tension and health of a zipline cable is a critical responsibility for zipline operators and enthusiasts alike. Regular inspection, testing, and maintenance are essential to minimize risks and provide a safe and exhilarating ziplining experience.

Remember, when it comes to ziplining, safety should always be the top priority.