The thickness of a zipline cable is a crucial factor in ensuring the safety and performance of your zipline adventure. Selecting the appropriate cable diameter is essential to support the weight of riders, maintain the cable’s durability, and provide an exhilarating experience. But how thick should zipline cable be?

For zip lines shorter than 200 feet, a 1/4-inch cable is suitable. For lengths between 200 and 500 feet, a 5/16-inch cable is recommended. And for any zip line over 500 feet or for commercial use, a 3/8-inch cable is advisable.

In this comprehensive guide, we’ll delve into the intricacies of zipline cable thickness, how to choose the correct diameter and offer maintenance tips for optimal performance.

Determining the Ideal Cable Thickness

1. Backyard or Recreational Use

For typical backyard or recreational settings, a medium-duty cable with a 4-inch diameter is suitable. It can support up to 600 pounds of weight and withstand 100 pounds per inch of zipline length. Approximately 300 feet of cable is needed to accommodate 600 pounds.

2. Small-Scale Commercial Use

In small-scale commercial settings, opt for a heavy-duty 4-inch diameter cable. It can handle up to 2,000 pounds of weight and withstand 200 pounds per inch of zipline length. About 800 feet of cable is necessary to accommodate 2,000 pounds.

Factors to Consider When Choosing a Zipline Cable Thickness

Choosing the right cable thickness for a zipline is crucial for ensuring the safety and enjoyment of its users as well as the longevity and sustainability of the zipline itself. Here are the key factors to consider:

1. Maximum Load Capacity:

- User Weight: Estimate the maximum weight of individual users and consider the total weight the cable will need to support at any given time.

- Safety Margin: Always select a cable with a significantly higher load capacity than the heaviest expected load to account for unforeseen stresses and to provide a safety buffer.

2. Length and Slope of the Zipline:

- Longer Lines: Longer ziplines might require thicker cables due to increased tension and potential for cable stretch.

- Steeper Slopes: Steeper ziplines exert more force on the cable and may require a thicker diameter to safely handle these forces.

3. Environmental Conditions:

- Weather Exposure: Cables exposed to harsh weather, such as extreme temperatures, humidity, or salt air, may require a thicker diameter or special coatings for added durability.

- UV Exposure: Continuous exposure to sunlight can weaken certain materials; appropriate material selection and thickness are vital.

4. Vibration and Wear:

- The zipline cable will endure regular vibrations and wear from the pulley system. A thicker cable might withstand this wear and tear for a longer period, reducing maintenance needs and ensuring consistent performance.

5. Flexibility and Handling:

- Installation: Thicker cables are heavier and more challenging to handle and install. Consider the logistics of installing the cable in your particular location.

- Movement: Ensure the cable provides enough flexibility for a smooth ride without compromising on safety.

6. Material Quality and Type:

- The type of material (e.g., galvanized steel, stainless steel) affects the strength, flexibility, and weather resistance of the cable. Choose a material appropriate for the zipline’s environment and usage.

7. Regulatory Standards and Best Practices:

- Adhere to any local, national, or international standards regarding zipline construction and safety, which may dictate minimum cable thickness and material specifications.

8. Cost and Budget:

- While safety should never be compromised for cost, the budget will inevitably play a role in the decision-making process. Thicker cables are more expensive, so balance cost with the requirements of safety and longevity.

9. Maintenance and Inspection:

- Consider the ease of inspecting the cable. Thicker cables may require more specialized equipment to inspect and maintain but may also have longer periods between necessary inspections.

10. Manufacturer’s Recommendations:

- Cable manufacturers often provide guidelines or recommendations based on the intended use of their products. Consult these recommendations and consider any case studies or examples they provide of similar applications.

Selecting the appropriate cable thickness for a zipline is a complex decision that must balance safety, performance, durability, and cost. It’s essential to consult with experienced engineers or zipline professionals and refer to industry standards to ensure the chosen cable meets all necessary requirements and provides a safe, enjoyable experience for all users.

Environmental Conditions: Consider the environmental conditions where your zipline will be located. Wet and humid environments may require thicker cables, such as stainless steel, to resist corrosion.

Wire Length: Determine the cable length needed for your zipline, considering any obstacles along the way. Vary the cable length based on rider heights to ensure safe rides.

Best Cable Sizes for Different Scenarios

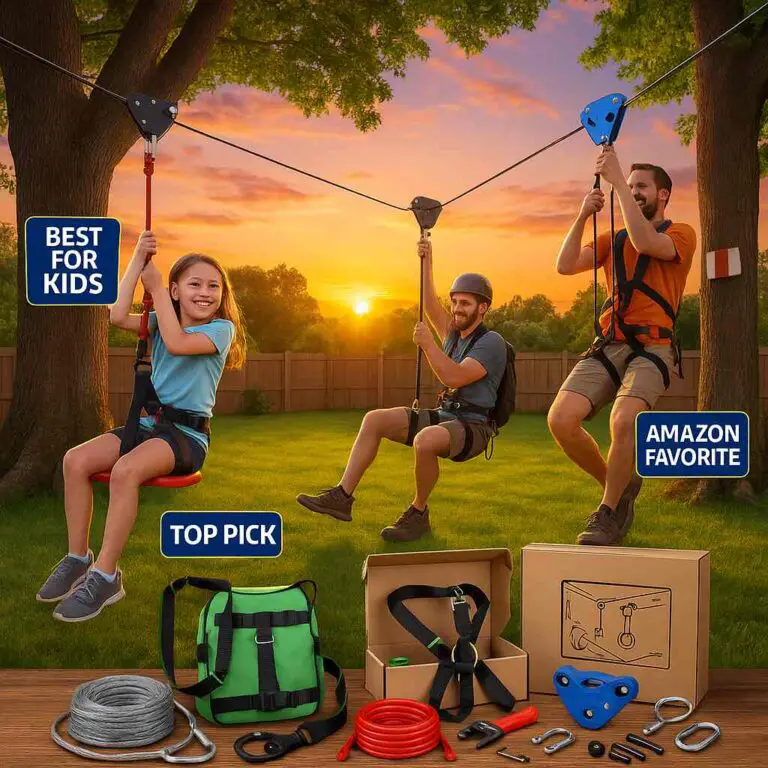

- Lighter riders (average weight of 250 lbs. each): 16-strand steel cable or 12-strand stainless steel wire rope.

- Weight range of 150 to 300 lbs. per person: 8-strand stainless steel wire rope or 6-strand galvanized aircraft cable.

- Heavy-duty platform for riders over 450 pounds: 16- or 12-strand galvanized aircraft cable.

Cable Size Chart:

- 3/16″ Cable: 3,700 lb Min Breaking Strength, Suitable for Zip Lines Up To 200 FT, Weight: 0.06 Per FT

- 1/4″ Cable: 7,000 lb Min Breaking Strength, Suitable for Zip Lines Up To 200 FT, Weight: 0.11 Per FT

- 5/16″ Cable: 9,800 lb Min Breaking Strength, Suitable for Zip Lines Up To 500 FT, Weight: 0.17 Per FT

- 3/8″ Cable: 14,400 lb Min Breaking Strength, Suitable for Zip Lines Up To 1,000 FT, Weight: 0.243 Per FT

Types of Zipline Cables and Their Impact on Performance

- Galvanized steel cable: Durable and anti-corrosive, ideal for outdoor use.

- Stainless steel cable: Suitable for corrosive environments like saltwater.

- Non-galvanized steel cable: Lower corrosion resistance, for non-corrosive applications.

Dos and Don’ts When Choosing Zipline Cable Thickness

When choosing the cable thickness for a zipline, it’s crucial to prioritize safety and performance. Here are some dos and don’ts to help guide your selection:

Dos:

- Do Consider Maximum Load: Factor in the weight of the heaviest users and any additional loads, such as gear. Choose a cable with a breaking strength that far exceeds this maximum expected load.

- Do Account for Environmental Factors: Consider the climate and environment where the zipline will be installed. Moisture, temperature extremes, and UV exposure can all affect cable longevity and performance.

- Do Follow Safety Standards: Adhere to national and international safety standards for zipline construction, which often specify minimum cable thickness and material requirements.

- Do Consult Professionals: Work with experienced zipline designers or structural engineers to ensure the cable is appropriate for the specific design and use of your zipline.

- Do Inspect Regularly: Plan for regular professional inspections of the zipline cable to identify wear, corrosion, or other issues early.

- Ensure the cable size aligns with zipline specifications.

- Measure your zipline accurately to determine cable requirements.

Don’ts:

- Don’t Underestimate Dynamic Forces: Remember that the forces on the zipline cable will include not just the weight of users but also additional dynamic forces from acceleration and deceleration.

- Don’t Skimp on Quality: Opting for a cheaper or thinner cable to save costs can compromise the safety and durability of your zipline. Always choose quality over cost.

- Don’t Ignore Manufacturer’s Recommendations: Cable manufacturers often provide guidelines for use based on the type and thickness of the cable. Ignoring these can lead to choosing a cable that’s not suited for your specific application.

- Don’t Overlook Future Use: Consider potential increased usage or heavier loads in the future. Choosing a slightly thicker cable can provide additional capacity and longevity.

- Don’t Forget about Expansion and Contraction: Cables can expand and contract with temperature changes. Make sure the cable and the system as a whole can accommodate these changes without compromising safety.

- Avoid reusing old, potentially damaged cables for safety reasons.

Zipline Variations and Their Correlation with Cable Thickness

Different zipline types and designs may require varying cable thicknesses to ensure optimal performance and safety. Understand how cable size influences the zipline’s functionality. When considering the variations in zipline design and their correlation with cable thickness, several factors come into play. Cable thickness is a crucial element in the safety and performance of a zipline. It affects the tension, capacity, and overall stability of the line.

- Tension and Stability: Thicker cables are typically able to support more weight and maintain stability better than thinner cables. This is because they have a larger cross-sectional area, which distributes the load more effectively and reduces stretching under tension.

- Weight Capacity: The weight capacity of a zipline is directly related to the thickness of the cable. A thicker cable can generally support a heavier load without compromising safety or performance. This is particularly important for commercial ziplines that need to accommodate a wide range of participants.

- Durability and Wear: Thicker cables also tend to be more durable and resistant to wear and tear. They can withstand the repeated stress of zippers (the pulleys used on ziplines) and adverse weather conditions better than thinner cables. This means they may last longer and require less maintenance over time.

- Ride Smoothness and Speed: The thickness of the cable can also affect the smoothness of the ride and the speed at which the rider travels. Thicker cables may provide a smoother ride because they are less prone to vibrations and movement. However, they might also create more resistance, potentially slowing down the ride depending on the trolley design and other factors.

- Installation and Cost: Thicker cables are generally more expensive and require more robust support structures due to their increased weight. This can affect the overall cost and complexity of installing a zipline. Additionally, the hardware used, such as clamps and anchors, needs to be compatible with the cable’s thickness to ensure safety and functionality.

Zipline Cable Thickness Legal and Safety Requirements

Legal and safety requirements for zipline cable thickness can vary significantly based on the country, state, or local jurisdiction, as well as the specific use of the zipline (e.g., commercial, recreational, educational). Here’s a general outline of the types of legal and safety considerations typically involved:

1. Standards and Regulations:

- International Standards: Organizations like the ASTM (American Society for Testing and Materials) and EN (European Norms) provide widely recognized safety standards for adventure activities, including ziplines.

- National and Local Regulations: Specific countries, states, or regions may have their own regulations governing amusement rides and aerial adventure courses. These can include specific requirements for cable thickness, material, and installation.

2. Design and Operational Guidelines:

- Safety Margins: Regulations often specify a minimum safety factor (e.g., the ratio of the breaking strength of the cable to the maximum expected load). Safety factors can range from 3:1 to 10:1 or higher, depending on the jurisdiction and situation.

- Material Quality: There may be requirements for the type of material used for the cable (e.g., galvanized or stainless steel) and for the cable’s resistance to weather, corrosion, and wear.

- Installation and Anchoring: Regulations might dictate how cables should be anchored and tensioned, as well as how often they should be inspected and maintained.

3. Regular Inspections and Maintenance:

- Inspection Frequency: Legal requirements often include regular professional inspections of the zipline, including the cable, platforms, and other equipment.

- Maintenance Standards: There may be specific guidelines for the maintenance of the cable, including criteria for when it should be replaced.

4. Operational Protocols:

- Usage Limits: Guidelines on the maximum weight of users and the number of users allowed on the line at one time.

- Emergency Procedures: Requirements for emergency procedures, rescue plans, and staff training.

5. Certification and Liability:

- Certification Requirements: Zipline operators may be required to obtain certification from recognized bodies, demonstrating compliance with safety standards.

- Liability Insurance: Operators are typically required to carry liability insurance to cover potential accidents and injuries.

6. Documentation and Record Keeping:

- Records of Inspections and Maintenance: Keeping detailed records of all inspections, maintenance, and repairs can be a legal requirement and is also a best practice for managing risk.

Important Considerations:

- Local Variations: Always check the specific regulations in your area, as requirements can vary widely even within the same country.

- Consult Professionals: Work with experienced engineers and legal professionals who specialize in amusement or adventure attractions to ensure compliance.

- Stay Updated: Regulations and standards can change, so it’s crucial to stay informed about the latest requirements and best practices.

Compliance with legal and safety requirements is not just about meeting the minimum standards; it’s about ensuring the well-being of all users and the longevity of the zipline. Regular updates, professional consultations, and a commitment to safety are key to operating a successful and compliant zipline adventure.

Conclusion

The choice of zipline cable thickness is not one-size-fits-all; it depends on factors such as rider weight, length, and environmental conditions. Thicker cables provide added security and durability, while proper maintenance and adherence to safety standards are essential for a safe zipline experience.