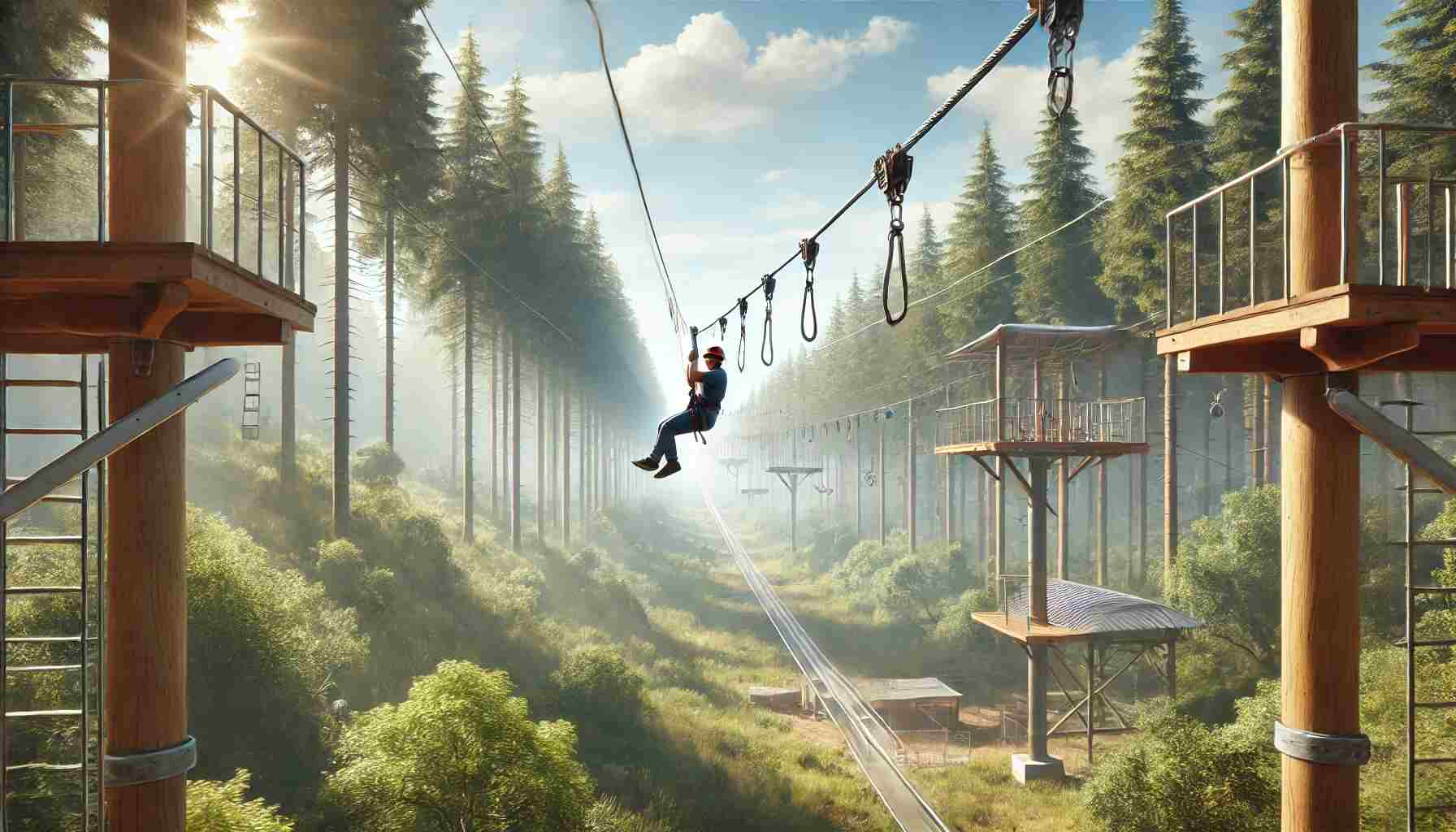

Commercial zip line kits have become a popular addition to adventure parks, resorts, and even private properties. They offer thrilling experiences for participants and can be a profitable investment for businesses. This comprehensive guide will cover everything you need to know about commercial zip line kits, from choosing the right one to installation, safety measures, and maintenance.

1. What is a Commercial Zip Line Kit?

A commercial zip line kit includes all the components needed to set up a zip line course. These kits are designed for heavy use in commercial settings such as adventure parks, camps, and resorts. They include cables, harnesses, trolleys, braking systems, and safety gear.

2. Benefits of Installing a Zip Line

a. Attracts Visitors

Zip lines are a major draw for adventure seekers, families, and tourists, making them a lucrative addition to any business.

b. Revenue Generation

Charging for zip line rides can be a significant source of revenue, with adventure parks and resorts often incorporating them into their package deals.

c. Enhances Customer Experience

Offering zip line rides can significantly improve the overall customer experience, encouraging repeat visits and positive reviews.

3. Key Components of a Zip Line Kit

a. Cable

The zip line cable is the most crucial component, typically made from high-strength galvanized or stainless steel.

b. Trolley

The trolley is the mechanism that glides along the cable, carrying the rider. It needs to be durable and smooth-operating.

c. Harness

Safety harnesses secure riders to the trolley, ensuring a safe experience.

d. Braking System

A braking system is essential to safely slow down and stop the rider at the end of the line.

e. Safety Gear

Helmets, gloves, and other protective equipment are included to ensure the safety of participants.

4. Factors to Consider When Choosing a Kit

a. Length of the Zip Line

Consider the total distance of the zip line course and choose a cable length accordingly.

b. Weight Capacity

Ensure the kit can support the weight of all potential riders.

c. Terrain and Environment

Consider the terrain where the zip line will be installed, including elevation changes and obstacles.

d. Safety Standards

Verify that the kit meets all relevant safety standards and certifications.

e. Budget

Balance quality and cost to find a kit that fits your budget without compromising safety.

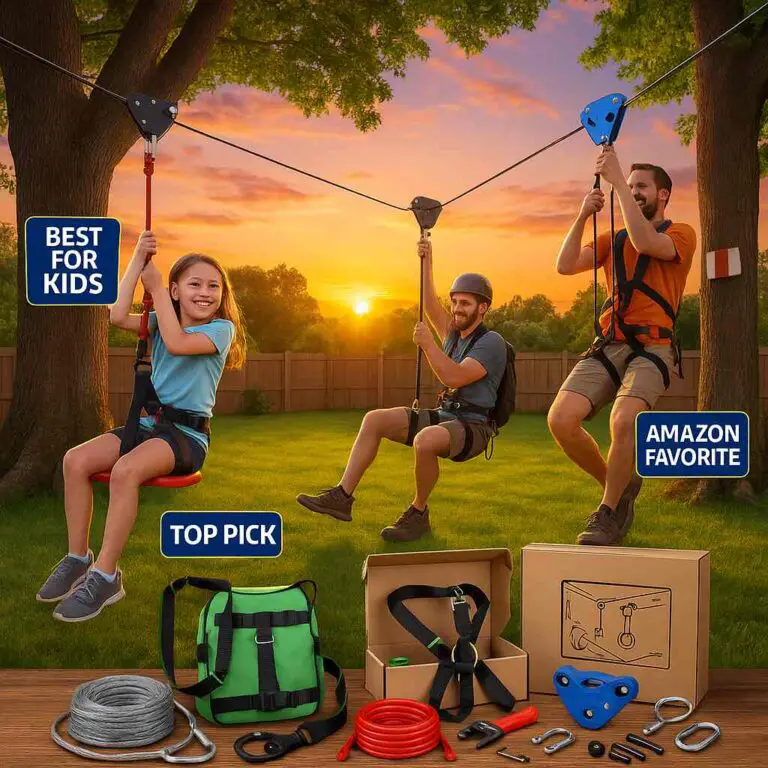

5. Top Commercial Zip Line Kits on the Market

a. Alien Flier Zip Line Kits

Known for their durability and smooth operation, Alien Flier kits are a top choice for commercial installations.

b. Zip Line Gear’s 1/2″ Extreme Zip Kit

This kit offers a robust setup with high weight capacity and advanced braking systems.

c. Rogue Pro Zip Line Kit by Spring Brake

A premium option with a spring brake system for smooth deceleration.

6. Installation Process

a. Planning and Design

Design the course layout, considering start and end points, and any obstacles.

b. Setting Up the Anchors

Install strong, secure anchors at both ends of the zip line. Trees, poles, or custom-built platforms are common choices.

c. Installing the Cable

Run the cable between anchors, ensuring it is taut and secure.

d. Adding the Trolley and Braking System

Attach the trolley to the cable and set up the braking system at the end point.

e. Safety Checks

Perform thorough safety checks before opening the zip line to the public.

7. Safety Measures and Standards

a. Compliance with Industry Standards

Ensure your zip line complies with industry standards such as those set by the Association for Challenge Course Technology (ACCT).

b. Regular Inspections

Conduct regular inspections of all components, especially the cable, trolley, and anchors.

c. Staff Training

Train staff thoroughly in operating the zip line and emergency procedures.

d. Rider Briefings

Provide clear instructions and safety briefings to all riders before they begin.

8. Maintenance and Inspection

a. Daily Checks

Perform daily checks on the cable tension, trolley condition, and braking system.

b. Monthly Inspections

Conduct more detailed inspections monthly, looking for wear and tear on all components.

c. Annual Professional Inspections

Hire a professional to conduct a thorough inspection annually to ensure the zip line remains in top condition.

9. FAQs about Commercial Zip Line Kits

Q: How long does it take to install a zip line?

A: Installation time can vary depending on the complexity of the course, but most installations can be completed in a few days to a week.

Q: What is the average lifespan of a zip line cable?

A: With proper maintenance, a zip line cable can last between 5 to 10 years.

Q: Can zip lines be installed in any terrain?

A: While zip lines can be installed in various terrains, some environments may require additional planning and engineering.

Q: Are there weight limits for zip lines?

A: Yes, most commercial zip lines have weight limits, typically ranging from 250 to 350 pounds.

10. Conclusion

Investing in a commercial zip line kit can significantly enhance the appeal of your business and provide a thrilling experience for your customers. By choosing the right kit, following proper installation procedures, and maintaining high safety standards, you can create a successful and enjoyable zip line course.