Wood is one of the oldest and most versatile building materials known to humankind. Whether it’s for construction, furniture making, or crafting, wood plays a crucial role in our daily lives. However, before wood can be used effectively, it must undergo a process called seasoning or drying. Seasoning is essential because it reduces the moisture content of the wood, making it more stable, durable, and suitable for various applications. Let’s explore the most efficient ways to season hardwoods vs. softwoods, understanding the unique characteristics of each type of wood and the methods best suited for them.

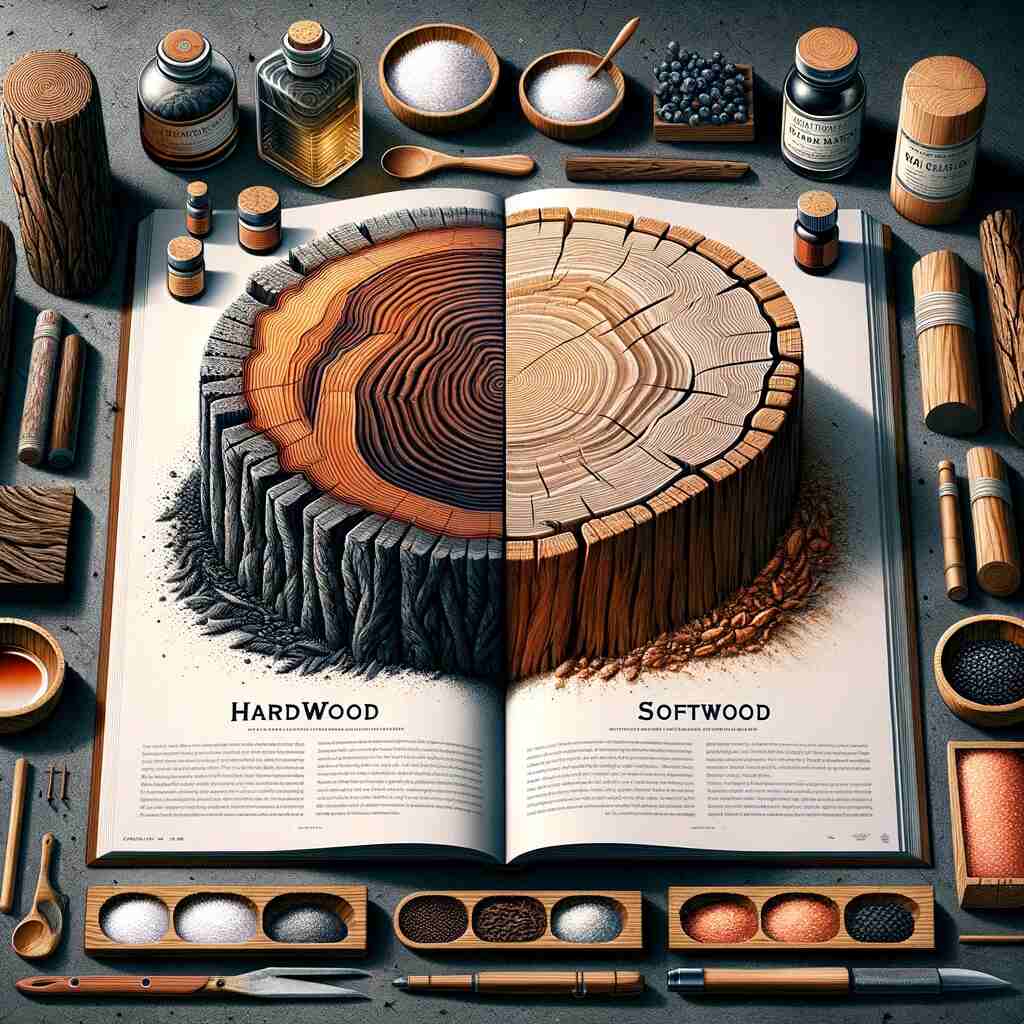

Understanding the Difference Between Hardwoods and Softwoods

Before diving into the specifics of seasoning, it’s crucial to understand the fundamental differences between hardwoods and softwoods. These differences have a significant impact on the drying process and the methods used.

Hardwoods

Hardwood trees come from deciduous trees that shed their leaves annually. They are known for their density and durability. Examples of hardwood species include oak, maple, cherry, and walnut. Hardwoods are often preferred for furniture making, cabinetry, flooring, and other high-quality applications due to their strength and attractive grain patterns.

Softwoods

Softwood trees, on the other hand, are typically evergreen trees that retain their leaves year-round. Softwoods are generally less dense than hardwoods and often grow faster. Common softwood species include pine, spruce, cedar, and fir. Softwoods are widely used in construction, outdoor decking, and various DIY projects.

The Importance of Proper Wood Seasoning

Wood contains a significant amount of moisture when it is first cut from a tree. High moisture content makes wood unstable and prone to various issues, such as warping, shrinking, cracking, and mold growth. Therefore, proper seasoning is essential to reduce the moisture content of wood to an optimal level.

Efficient wood seasoning offers several advantages:

- Dimensional Stability: Properly seasoned wood is less likely to warp, twist, or crack during and after processing.

- Improved Strength: Dried wood is stronger and more resilient than green or wet wood.

- Reduced Weight: Seasoning reduces the weight of wood, making it easier to handle and transport.

- Enhanced Workability: Dry wood is easier to cut, shape, and join, making it ideal for various woodworking projects.

- Decreased Risk of Decay: Lower moisture content inhibits mold and fungal growth, extending the wood’s lifespan.

To achieve these benefits, you must choose the right method and approach to season hardwoods and softwoods effectively.

Seasoning Methods for Hardwoods

Seasoning hardwoods requires careful attention to detail, as they are denser and tend to dry more slowly than softwoods. Here are some of the most efficient methods for seasoning hardwoods:

Air Drying

Air drying is a traditional and cost-effective method for seasoning hardwoods. It involves stacking the wood in a well-ventilated area and allowing it to dry naturally over time. Here’s how to do it:

- Prepare the Stacking Area: Choose a location with good airflow and protection from direct sunlight and rain. Create a raised platform or use wooden stickers to separate the lumber, ensuring even airflow between each piece.

- Stack the Wood Properly: Stack the hardwoods with spaces (stickers) between each board to promote air circulation. The sticker thickness should be uniform to prevent uneven drying.

- Cover the Stack: Protect the wood from rain and excessive moisture, but allow air to flow freely. You can use a tarp or a specially designed lumber cover for this purpose.

- Monitor Moisture Content: Regularly check the moisture content of the wood using a moisture meter. When the wood reaches the desired moisture level (usually around 10-12%), it’s ready for use.

Air drying hardwoods can take several months to several years, depending on the wood species, thickness, and local climate conditions. It’s essential to be patient and monitor the process closely to prevent over-drying or moisture reabsorption.

Kiln Drying

For those who require a faster and more controlled drying process, kiln drying is an efficient method for seasoning hardwoods. Kilns are specially designed chambers that use heat, humidity, and ventilation to accelerate the drying process. Here’s how it works:

- Prepare the Kiln: Load the hardwood lumber into the kiln. Ensure that the wood is stacked evenly and spaced to allow for proper air circulation.

- Control Temperature and Humidity: Gradually raise the temperature and control the humidity levels inside the kiln to remove moisture from the wood. The specific temperature and humidity settings depend on the wood species and thickness.

- Monitor the Process: Use sensors and monitoring equipment to track temperature and moisture content continuously. Adjust the kiln settings as needed to achieve the desired moisture level.

- Cooling and Equalization: After the wood reaches the target moisture content, gradually reduce the temperature and humidity levels to cool the wood and prevent stress-related defects.

Kiln drying significantly reduces the time required to season hardwoods compared to air drying. It allows for precise control over the drying process, making it suitable for commercial applications and woodworking businesses. However, kiln drying can be expensive due to the energy and equipment costs involved.

Seasoning Methods for Softwoods

Softwoods tend to have a higher moisture content and lower density than hardwoods, making them generally easier to season. However, proper seasoning is still essential to ensure the wood’s stability and usability. Here are some efficient methods for seasoning softwoods:

Air Drying

Air drying is also a suitable method for seasoning softwoods, and the process is quite similar to that used for hardwoods. However, softwoods typically dry faster due to their lower density. Here are the steps to air dry softwoods:

- Select a Drying Location: Choose a well-ventilated area with protection from direct sunlight and rain for stacking the softwood lumber.

- Stack the Wood: Stack the softwood boards with uniform sticker spacing to promote airflow between each piece.

- Cover and Monitor: Use a cover or tarp to protect the wood from excessive moisture while allowing air to circulate. Regularly monitor the moisture content until it reaches the desired level.

Softwoods can often be air-dried in a few months, making this method cost-effective for small-scale operations and DIY projects.

Solar Kiln Drying

Solar kiln drying is a sustainable and cost-effective method for seasoning softwoods. It combines the benefits of air drying and kiln drying while using renewable energy from the sun. Here’s how to set up a solar kiln for drying softwoods:

- Build a Solar Kiln: Construct a specially designed solar kiln chamber with a transparent roof or wall facing the sun. This design allows sunlight to heat the kiln, creating a controlled drying environment.

- Load the Wood: Stack the softwood lumber inside the solar kiln, ensuring proper spacing and airflow between boards.

- Monitor Temperature and Humidity: Use sensors and monitoring equipment to track temperature and humidity levels inside the kiln. Adjust ventilation and temperature as needed to achieve the desired moisture content.

- Cooling and Equalization: Gradually reduce the temperature and humidity levels to cool the wood and prevent stress-related defects after reaching the target moisture content.

Solar kiln drying is an excellent choice for those looking for an energy-efficient and eco-friendly method to season softwoods. It harnesses the power of the sun to reduce drying times while maintaining control over the process.

Considerations for Both Hardwoods and Softwoods

While the specific seasoning methods may vary for hardwoods and softwoods, some considerations apply to both types of wood:

Initial Moisture Content

The starting moisture content of the wood is a crucial factor in the seasoning process. Green wood, freshly cut from the tree, can have moisture levels exceeding 50%. To ensure efficient seasoning, it’s essential to allow the wood to reach an equilibrium moisture content (EMC) suitable for its intended use. EMC varies depending on the local climate and application but typically ranges from 6% to 12%.

Wood Thickness

Thicker pieces of wood take longer to season than thinner ones. It’s important to stack wood of similar thickness together to ensure even drying. Additionally, thicker pieces may require more time in the kiln or drying chamber to reach the desired moisture content.

Stack and Stick Placement

Proper stacking and sticker placement are critical for both air drying and kiln drying. Stickers (small pieces of wood) are placed between each layer of lumber to promote airflow and prevent the wood from sticking together. Proper sticker spacing and alignment help ensure even drying and reduce the risk of defects.

Monitoring Moisture Content

Regularly monitoring the moisture content of the wood is essential throughout the seasoning process. Moisture meters, which are readily available and affordable, allow you to measure the wood’s moisture content accurately. Keep a log of moisture readings to track progress and ensure that the wood reaches the desired moisture level.

Preventing Mold and Fungal Growth

Both hardwoods and softwoods can be susceptible to mold and fungal growth if exposed to excessive moisture during seasoning. Proper ventilation and protection from rain and excessive humidity are essential to prevent these issues.

Preventing Insect Infestations

Wood, especially when stored outdoors, can be vulnerable to insect infestations. Applying insect repellent treatments or using protective coverings can help prevent insect damage during seasoning.

Conclusion

Seasoning hardwoods and softwoods efficiently is crucial for maximizing the performance and longevity of wood products. While both types of wood require careful attention to the seasoning process, the specific methods and timelines may differ. Hardwoods, with their higher density, often benefit from controlled kiln drying, while softwoods can be effectively air-dried or dried in solar kilns.

Ultimately, the choice of seasoning method depends on various factors, including the type of wood, its intended use, available resources, and time constraints. Regardless of the method chosen, proper preparation, monitoring, and attention to detail are key to achieving the desired moisture content and producing high-quality, stable wood products. Whether you’re a professional woodworker or a DIY enthusiast, mastering the art of wood seasoning is essential for successful woodworking projects and the preservation of this timeless and versatile material.